Harmonics are costing you money!

If you operate a business that uses electricity – and which business doesn’t – then it’s a fact that harmonics are costing you money, says Julian Grant of Chauvin Arnoux. To find out how and what you can do about it, read on!

If you’re thinking that I’ve already written about harmonics in this series, you’re right, but I make no apologies for revisiting this important topic. Why? Because these days harmonics are present in every power system and they’re a major cause of unnecessary expenditure. Furthermore, the overall impact of harmonics is often poorly understood.

Let’s start with a very brief reminder of what harmonics are and where they come from. In simple terms, harmonics are currents (or voltages) at frequencies that are integer multiples of the power frequency. For 50 Hz supplies, this means 100 Hz, 150 Hz, 200 Hz, 250 Hz and so on. The source of harmonics is non-linear loads – that is, loads where the current isn’t proportional to the applied voltage throughout the whole of each voltage cycle. In the modern world, non-linear loads are everywhere. LED lighting systems, variable speed drives, computers, office machines and televisions are just a few examples.

But why do harmonics matter, and why do they cost money? One answer is that they generate unwanted heat. In a balanced three-phase power system with no harmonics the current in the neutral conductor will be zero. Introduce harmonics, however, and things are very different because the so-called triplen harmonics – those that are multiples of three times the power frequency (150 Hz, 300 Hz, 450 Hz, etc.) – don’t sum to zero in the neutral conductor even in a perfectly balanced installation. In fact, the harmonic currents add, so in such cases the neutral will potentially be carrying a substantial current.

Unless the neutral conductor has been sized to take this into account, it may well overheat and fail. And even if it is properly sized – which means a larger and more costly conductor – that unwanted heat represents wasted energy and whoever pays the electricity bill pays for that energy.

Of course, heating in neutral conductors is not the only problem caused by harmonics. Because they can produce a magnetic field that rotates in the ‘wrong’ direction in a motor, opposing the field produced by the power frequency current, they can reduce the torque the motor produces and increase vibration. As a result, it may be necessary to use a bigger motor, and because of the vibration, the life of the motor and the equipment it’s driving may be reduced. Once again, this translates to increased costs.

Harmonics are also a major cause of excess heating in power transformers, which means that if significant levels of harmonics are present in the supply system, larger and more expensive transformers will be needed. It may be easy to assume that this is a problem for the supply company rather than the consumer, but bear in mind that anything that increases costs for the power company will ultimately result in higher energy prices. And, if harmonic levels in an installation are too high, the power company may well refuse to provide a supply!

Moving on from unwanted heating, another and much less well-known problem associated with harmonics is their effect on power factor. The usual assumptions are that power factor issues are related purely to inductive loads and they can be corrected by adding capacitors to the power system. Unfortunately, this is only true in power systems where no harmonics are present.

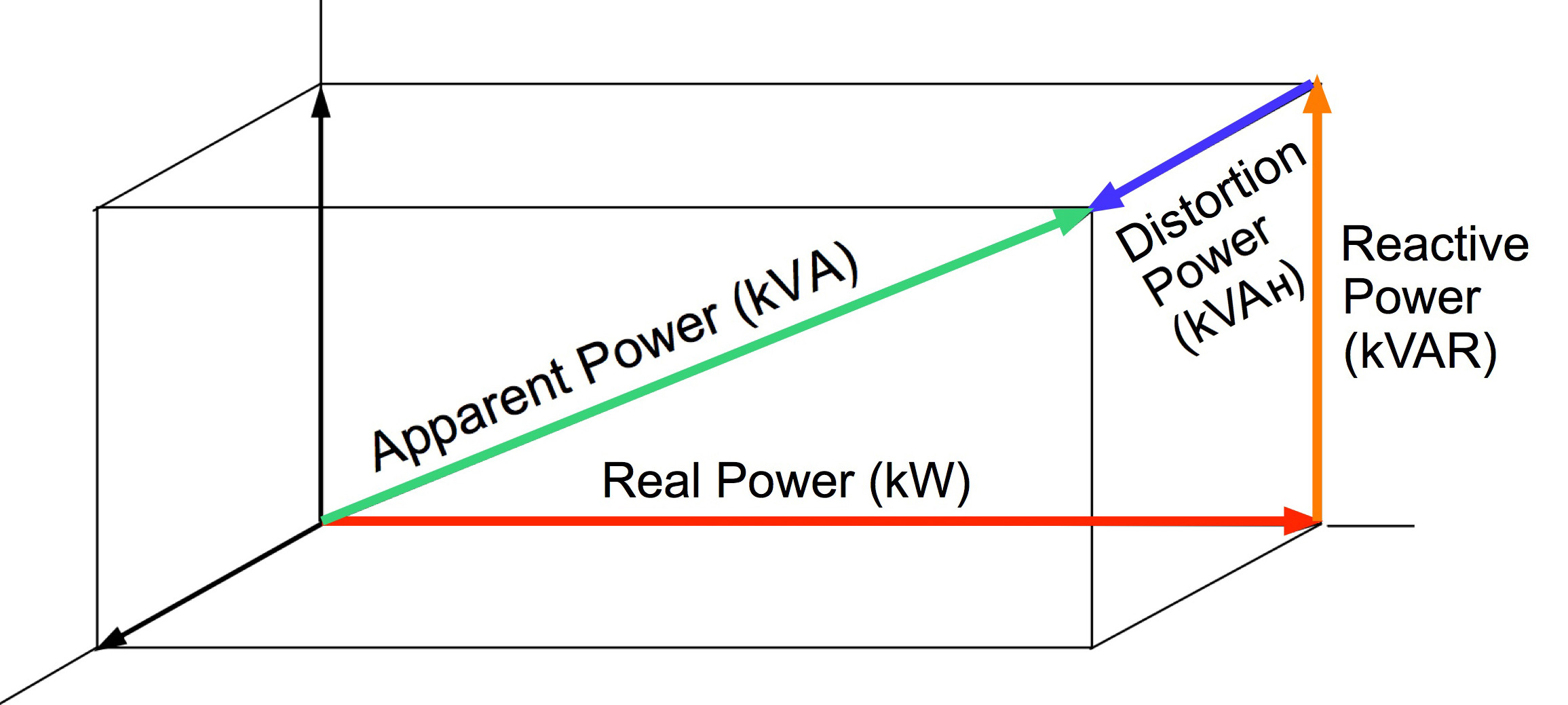

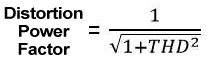

The real situation is that power factor has two components. The first is the displacement power factor and this corresponds to the usual view of power factor as described in the last paragraph. The second component is the distortion factor (DF), which relates directly to harmonics. Distortion factor is often neglected or ignored but, because of the prevalence of harmonics in today’s supply systems, it is no longer reasonable to do this.

The overall true power factor for a machine or installation is given by displacement power factor multiplied by distortion factor and, since in practice distortion factor is always less than 1, the true power factor is always worse than the displacement power factor considered alone. And it’s the true power factor that determines how much non-productive energy – which has to be paid for – is taken from the supply system.

Clearly there’s an incentive to improve both the displacement power factor and distortion factor but there’s a complication: distortion factor cannot be corrected by adding capacitors. In fact, the addition of capacitors can actually make the situation worse, because resonances may occur at one of the harmonic frequencies. Achieving an effective solution will depend on the application but will typically involve the use of both capacitors and chokes.

By now it should be readily apparent that harmonics in the supply system are undesirable and also a potent source of increased costs. What’s to be done? Fortunately, there are many practical and effective ways of mitigating harmonics. The first steps, however, are always the same – assess and investigate the problem. The best way to do this is to use a modern portable energy logger (PEL), such as the PEL104 or PEL106 from Chauvin Arnoux.

These compact and affordable instruments can be readily connected at various points in an electrical installation to measure and record the level of harmonics present, along with many other parameters such as voltage, current and power factor. The data provided by an exercise like this will give a good insight into the level and types of harmonic present, together with an indication of their source. This will allow suitable mitigation measures to be devised, and once they have been implemented, further tests with the PEL will confirm their effectiveness.

In today’s highly competitive business world, you can’t afford and shouldn’t be paying for harmonics in your supply system. So make sure you don’t – invest in a PEL and set out on the path to savings today!