While the fruit processor was not aware of any specific energy-related issues, they recognised the value in identifying the major energy consumers within the factory and exploring opportunities for energy savings and efficiency improvements. The first step was to engage Smart Energy Solutions NI, an expert in energy efficiency, to inspect the production processes and, where possible, take manual readings from panel meters to provide an indication of energy usage. Discussions were also held with the Operations Manager at the factory to determine which items of equipment were likely consuming more energy. The data collected was used to design a real-time, cloud-based monitoring solution for key circuits. This allowed energy reduction efforts to be precisely focused on the areas with the greatest potential for savings.

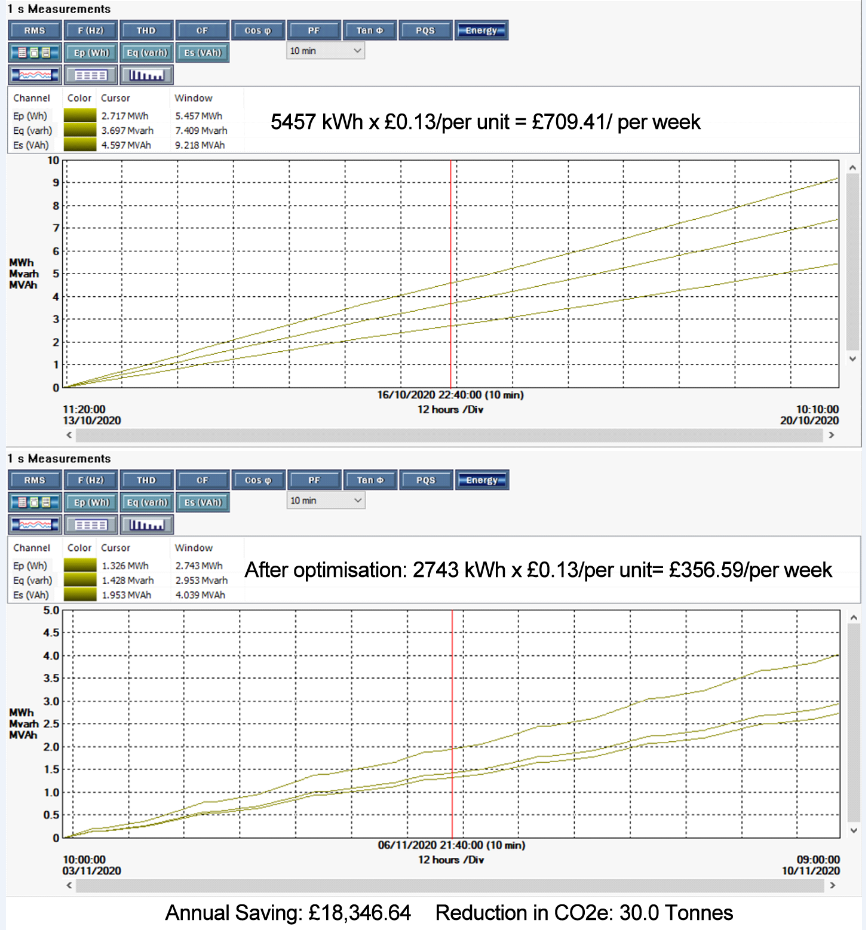

Continuous monitoring enables quick and reliable assessment of energy efficiency measures taken, while also allowing their long-term performance to be verified months or even years after implementation. As part of the initial steps in the project, Chauvin Arnoux three-phase power and energy loggers (PELs) were installed on the plant’s main power-consuming equipment. Almost right away, the data revealed something both interesting and alarming: the refrigeration system for the main cold store was running non-stop, racking up an energy bill of around £650 per week based on the energy prices at the time. When the cold store service provider was called in to investigate, they discovered the system had been set to manual override — likely a result of some earlier issue with the control system.