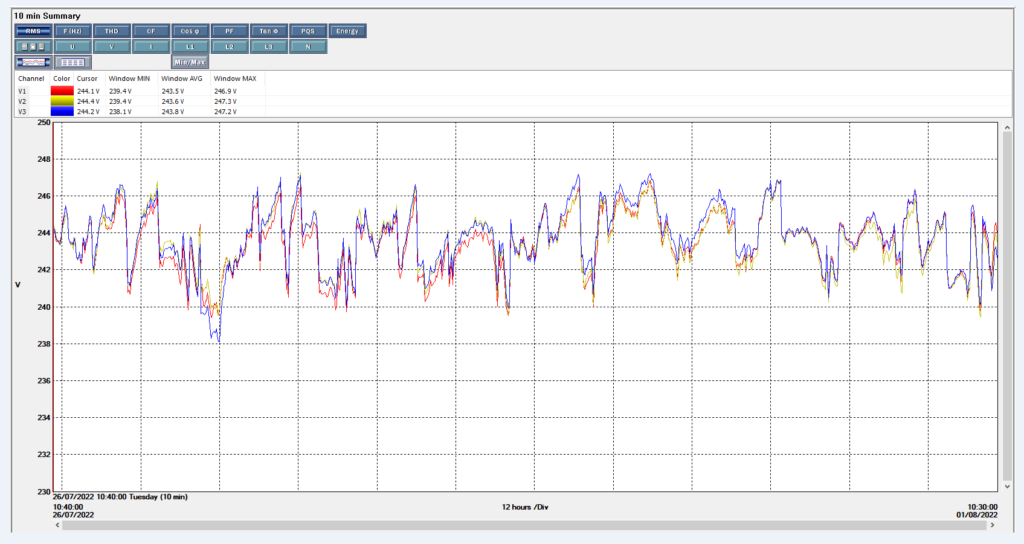

Since the PEL104 was set to measure and record voltage, current, power factor and harmonics, we also discovered our average supply voltage was sitting at 243.6V phase-neutral, and 422.3V phase-phase. More on that later. We also recorded the average power factor on the downstairs lighting circuit of 0.905.

In previous articles we have discussed in detail the relationship between Real Power, Apparent Power, Reactive Power, and Power Factor. Suffice to say here that Real Power (Watts) = Apparent Power (VA) × Power Factor.

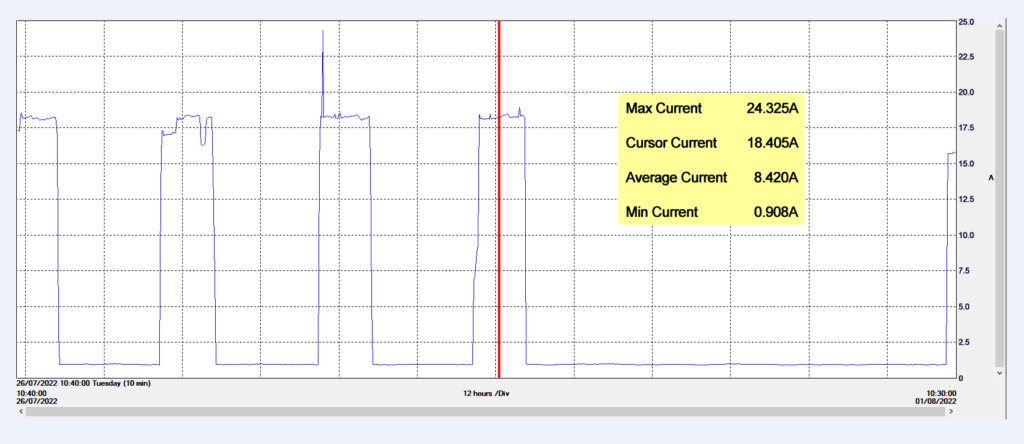

Accordingly, at 18.405A and 243.6V with 0.905PF we were consuming 4,058W or just over 4KW, as compared to the 8,412W we calculated would be consumed if all of the lights had been switched on.

Other points to note in the 6-day current log, were the visible increase in consumption on the Thursday morning, which occurred when a conference room was used for a short while, and it was somewhat comforting to see our out of hours usage down a 0.908A, although it will be nice when we find out where that is going.

Having measured and logged the lighting consumption we set about replacing all of the fluorescent tubes with LED lighting. The 4 tube fittings in the office were all changed to 1200X600 46W LED panels and the 100W tubes in the rest of the building replaced with 36W T8 8ft LED Tubes.

Interestingly, this “high” supply voltage is extremely common in the UK, and without getting into too much detail in this article, the utility could relatively easily reduce it. This could either be done at the local substation transformer by means of its incorporated tap changer, or at the higher transmission voltage level for a wider impact. Such action would both reduce the energy consumption (and bills) of their individual customers, and perhaps more importantly, reduce the total instantaneous energy demand on the grid. The latter being something that could help significantly in the current climate of impending potential energy shortages.

With regards to our own energy saving mission, having changed all of our fluorescent lighting for LED replacements, we have now started another power and energy logging session and will report back on the findings in the next part of this case study.