[vc_row css=”.vc_custom_1559969760488{margin-top: 90px !important;}”][vc_column][vc_column_text]

Power Quality Issues – Part 1 – Harmonics

Harmonics issues within an electrical installation frequently go overlooked due to a lack of understanding or awareness of them. This then often leads site and facility managers experiencing problems within their installations to focus on the symptoms rather than the underlying cause of those problems. In this, the first in a series of short articles on power quality issues, Julian Grant – General Manager at Chauvin Arnoux UK, explains the causes, symptoms and some solutions to the problems of harmonics.

Within the last 30 years there has been a big increase in the number of non-linear loads connected to the electrical network, including computers and associated IT equipment, uninterruptable power supplies, variable speed motor drives, electronic lighting ballasts, and LED lighting, to name just a few. The growing use of such equipment and the application of electronics in nearly all electrical loads are beginning to have some worrying effects on the electricity supply. It is estimated that today over 95% of the harmonic interference within an installation is generated by equipment within that installation.

When a linear electrical load is connected to the supply it draws a sinusoidal current at the same frequency as the voltage, however, non-linear loads draw currents that are not necessarily sinusoidal.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_single_image image=”995″ img_size=”full”][/vc_column][vc_column width=”1/2″][vc_column_text]The current waveform can become quite complex, depending on the type of load and its interaction with other components in the installation. These non-linear loads increase current, and in severe cases voltage, distortion in the electrical supply, which can lead to significant energy losses, shortened equipment lifespans, and reduced efficiency of devices.

Waveform distortion can be mathematically analysed to show that it is generally equivalent to superimposing additional frequency components onto the original 50Hz sinewave. These frequencies are harmonics of the fundamental frequency, and can sometimes propagate outwards from the non-linear loads causing problems elsewhere on the electrical installation.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Regardless of how complex the current waveform becomes it is possible to deconstruct it into a series of simple sine waves using Fourier analysis.

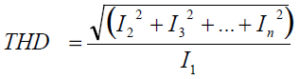

One of the measures often used to indicate the amount of harmonic distortion present in an electrical installation is total harmonic current distortion or THDi. This is a ratio of the sum of all the harmonic currents to the current at the fundamental frequency described by the equation: –

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text]Harmonic currents have negative effects on almost all items on the electrical system by upsetting sensitive electronic devices and causing dielectric thermal and mechanical stresses.

[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text]Harmonic currents have negative effects on almost all items on the electrical system by upsetting sensitive electronic devices and causing dielectric thermal and mechanical stresses.

The most significant of these include computer and other IT equipment crashes and lockouts, flickering lights, electronic card failures in process control equipment, power factor correction equipment failure, high load switching failure, neutral conductor overheating, unexpected circuit breaker operation and inaccurate metering.[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_single_image image=”994″ img_size=”full”][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Some of these, such as flickering lights and IT equipment crashes are, at the least, an irritant to businesses. Electronic card failures on production lines or process control equipment can cost businesses in unplanned down-time. Worst of all though, failure of power factor correction and electrical distribution equipment, cables, transformers, motors and standby generators can be catastrophic. At the least the presence of harmonics will cause reduced electrical efficiency within the installation and excessive power consumption which you will be paying for.

The internal resistance of a capacitor reduces as frequency rises, and at high frequencies can appear almost as a short circuit. Power factor correction capacitors are generally designed to operate at the fundamental frequency, and the lower impedance seen by the higher frequency harmonic currents result in an increased amount of capacitor overheating. It is also possible to experience permanent damage to capacitors due to parallel resonance occurring between them and transformers.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_single_image image=”998″ img_size=”full” alignment=”center”][/vc_column][vc_column width=”1/2″][vc_column_text]Resistive heating is proportional to the square of the harmonic order, and so it follows that the greater the number of higher order harmonics that exist the greater the heating effect.

At the least this will lead to large increases in iron losses, and therefore power consumption, in rotating machines and transformers, as well as increased eddy current losses in transformers. In the worst cases fires in wiring and distribution systems or even catastrophic transformer failure.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column][vc_column_text]Apart from losses due to heating effects, motors in particular can be significantly negatively impacted by harmonics due to torsional oscillation of the motor shaft. Torque in AC motors is produced by the interaction between the air gap magnetic field and induced currents in the rotor. When a motor is supplied non-sinusoidal voltages and currents, the air gap magnetic fields and the rotor currents will obviously contain harmonic frequency components. The harmonics are grouped into positive, negative and zero sequence components. Positive sequence harmonics (1, 4, 7, 10, 13, etc.) produce magnetic fields and currents rotating in the same direction as the fundamental frequency harmonic. Negative sequence harmonics (2, 5, 8, 11, 14, etc.) develop magnetic fields and currents that rotate in a direction opposite to the positive frequency set, and zero sequence harmonics (3, 9, 15, 21, etc.) do not develop usable torque, but produce additional losses in the machine. The interaction between the positive and negative sequence magnetic fields and currents produce torsional oscillations of the motor shaft. These oscillations result in shaft vibrations, and if the frequency of oscillations coincides with the natural mechanical frequency of the shaft, they become amplified and severe damage to the motor shaft may occur. It is sometimes possible to literally hear a transformer or motor “sing or growl” due to these vibrations and this is often one of the first observed indications of a harmonic problem.

Some of the most troublesome harmonics are the 3rd, and odd multiples of the 3rd, i.e. the 9th, 15th etc. These harmonics are called “triplens”. The triplen harmonics on each phase are all in phase with each other which will cause them to add rather than cancel in the neutral conductor of a three phase four wire system. This can overload the neutral if it is not sized to handle this type of load.[/vc_column_text][/vc_column][/vc_row][vc_row][vc_column width=”1/2″][vc_column_text]Fortunately, the identification and measurement of harmonics is easily achieved using a power quality analyser or power and energy logger (PEL) with harmonic capabilities, and while they cannot be eliminated, since they are generated by the various loads in the installation, they can be confined to an area as close to the polluting load as possible in order to prevent them from reaching the overall network.

The main methods used involve installing passive or active filtering or isolating systems designed to limit the deterioration of energy quality and other harmful effects as well as the use of tuned power factor correction equipment. Once the harmonics are “under control”, the associated problems, power losses, equipment failures and outages, and energy costs will be reduced.

Harmonics can be a major issue in the modern electrical installation, becoming increasingly more important as more switching and smart loads are introduced. Harmonics must be monitored regularly in order to verify their levels and prevent potential failures or high losses.[/vc_column_text][/vc_column][vc_column width=”1/2″][vc_single_image image=”996″ img_size=”full” alignment=”center”][/vc_column][/vc_row][vc_row content_placement=”middle”][vc_column][vc_btn title=”Download PDF” color=”orange” align=”center” link=”url:https%3A%2F%2Fcauk.tv%2Fwp-content%2Fuploads%2F2019%2F03%2FPower_Quality_Issues_Harmonics.pdf||target:%20_blank|”][/vc_column][/vc_row]